We had a very productive meeting last Sunday.

We learned that if the Indigo Pot gets over 135 F, the indigo starts to solidify and the pot gets a foam on top. Once it cools down to 135 F the pot dyes ok, no harm done. So don’t heat the dye pot over 135 F.

Sandy, Christine, Sharolene, Marcia, and Frank dyed their warps. At this point it sounds like everyone has completed dying their Ikat warps. So, there is no need to do Indigo dyeing for a while.

Anne, Sharolene, and Marcia dug madder. There was not enough to use for dye, but Christine and Julie took what was found to plant in their gardens. We had a discussion about processing madder root so it can be used for dyeing. Frank showed us tools that you can use to clean the madder and process it, including a scrub pad, tenderizing tool, and potato peeler.

We then talked about the Pin Loom Friendship project. Marcia showed her collection of samples made on pin looms and books on pin loom weaving. Marcia also lent pin looms out to Christine, Julie and Frank. Sandy decided she would buy her own Zoom loom to use. Marcia gave an impromptu demonstration of how to weave on a pin loom. Sharolene showed us a scarf she made out of pin loom squares. She spun all the yarn for the scarf and added a lace knit edging around the scarf.

Frank also showed Julie how to make booklets from our handmade paper and showed his handmade fabric booklet cover.

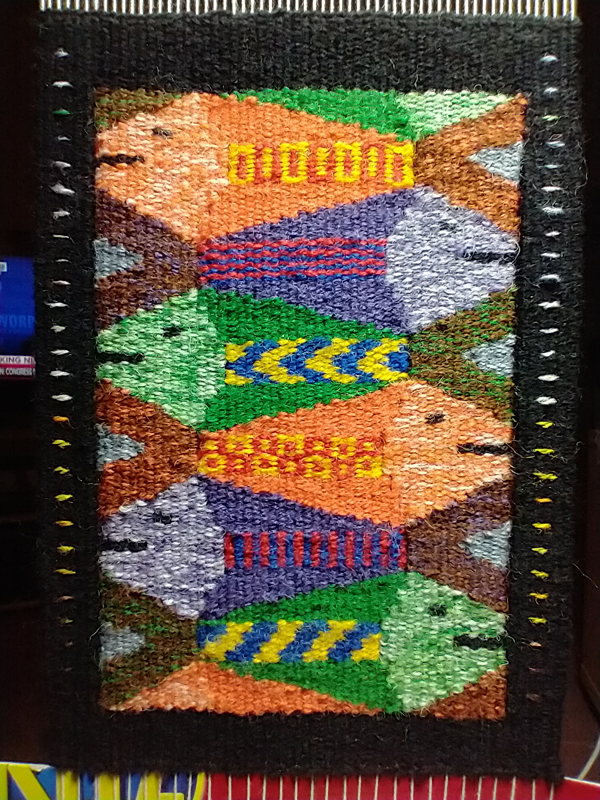

Other show and tell – Marcia and Sharolene showed us their ikat scarves.

And Sharolene showed us her turned taquete towel.

For the pin loom project, we decided:

- We will be using 4 inch pin looms.

- Worsted weight yarn or thinner. Sharolene’s scarf was more of a fingering weight.

- 6 inch needles to weave with.

- We will be weaving plane tabby squares. We will NOT be weaving bias squares.

We then discussed what we wanted to do about our donation for the CHNC auction. We decided to donate a spinning project.

- Anne will donate colored wool she drum carded. She will store the wool until the February meeting.

- Frank will donate a drop spindle and some commercial roving.

- Marcia will donate knitting needles and a knitting pattern.

- Sandy will donate a weaving pattern.

- Marcia will buy tissue paper and ribbon for the Guild to package everything with.