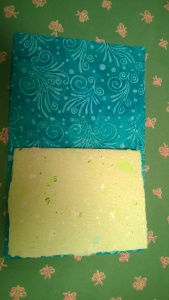

We met on an extremely hot day and met early to beat the heat. The subject for our September meeting was making covers for handmade paper notebooks. Frank Mikulastik was our fearless leader. Frank makes 40 pieces of handmade paper in his kitchen on Sunday afternoons! Frank is a good teacher and showed us how to size a cover for the size of the paper, told us what materials to use and showed us how to sew a signature into a cover. He is quite inspiring with his own indigo dyed notebook covers.

Sandy brought some leather that we cut for notebook covers. She was able to cut them to size with a metal ruler and a box cutter. She made them big enough for two signatures. It is a nice pliable soft leather and will be great for notebook covers.

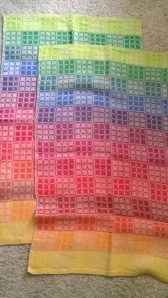

Sharolene shared her madder dyed fiber that she dyed in the last few weeks, linen towel that she just pulled off the loom and cotton from the garden. The madder process was

Attendees at meeting were: Phyllis, Frank, Sharolene, Sandy, Marsha and Carol Lewis (new member).